Hello, guys.

After playing a little with 2 different nunchuck sizes, I decided that 350mm (14") is too long for me, so I customized my metal nunchuks.

I had 2 steel nunchuks of ~350mm length (14”) and I wanted to cut them to ~300mm (12”), but it's the same procedure if you are making a new nunchuk out of a pipe.

I cut the first one with a hacksaw and the other with a pipe cutter for comparison.I'm not making a tutorial; everybody knows how to use a hacksaw, right? I'm posting only a few tips.

1. hacksaw

materials:

-pipe (an existing nunchaku in my case)

-hacksaw: you should buy a new blade, an old-dull blade will cost you more time.

-sandpaper

procedure:

Just measure carefully, keep it steady for a straight cut and keep your da** fingers away.

Nunchuck after cutting, without sanding:

Finish:

Use a medium sandpaper to remove the burr edge and a fine one if necessary.

The cut is very clean, sandpaper and a bit of patience is enough.

2. pipe cutter

materials:

-pipe

-pipe cutter

-bench grinder

procedure:

Adjust the cutter to the width of the pipe, turn it around and adjust the cutter width from time to time. My pipe is 1” width stainless(?) steel and about 0.8mm (1/32”) thick, the cheap pipe cutter cut it like a knife through butter.

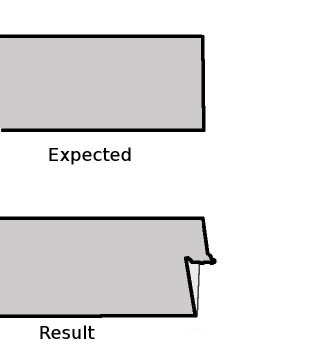

The problem was: the resulting cut was skew and left a big burr on the edge, also I had to “straighten” the cut, that was too much for sandpaper and file so I HAD to use the bench grinder.

Note: I have a the-cheapest-i-could-find pipe cutter (~6.0 USD).

Using the bench grinder.

SAFETY FIRST. MUST use safety goggles. Use common sense.

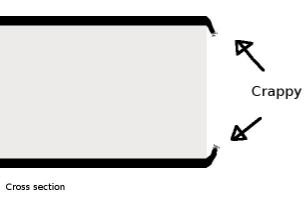

Incorrect pipe angle for the grinder: this will “bend” some material inward and you will get a burr edge inside the pipe.

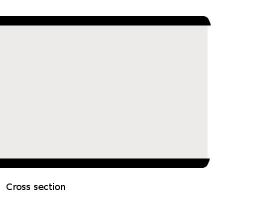

Correct angle. Use a medium or coarse stone, rotate the pipe slowly. This will remove material evenly, and you can remove big chunks. Warning, you can easily remove too much and end up with a nunchuk 10 or 20 mm shorter than expected.

Rounding edges.

Optionally you can do this after cutting with the hacksaw, if you are too lazy to use sandpaper.

Use a fine stone for soften (round) the edges. Apply very little pressure to the stone. Pass the pipe quickly and softly, you do not want to remove material but polish a little bit. Again, it's quite easy to remove far too much material and screw up you job.

Start with a ~60 degrees angle. Rotate quickly the pipe on full turn.

Then 45-30 degrees.

End with a very slim angle ~10 degrees or less.

3. results

Finally, both nunchuks (4 pipes) are the same length, straight cut and have a very good finish. So, you can get good results with either method; the big difference is cost.

Time

Hacksaw: total time ~10 minutes (5 cutting, 5 sanding)

Pipe cutter: total time ~20 minutes (2 cutting, >15 grinding)

Money = tools you need

Hacksaw: a hacksaw is a tool every house, every man!, must have. Just spend ~1 buck (US Buck) in a blade and sandpaper.

Pipe cutter: I didn't have one, nor any of my friends, it is not a common tool... so spent ~6.0 USD. I have a bench grinder for some other stuffs around my house but it's rare for people to have one in home.

Big winner: the old hacksaw

The pipe cutter did cut faster, silent, cleaner (without debris) and easier; just as I expected, but requiring the use of a bench grinder was a big drawback and big waste of time.

-------------------

Well, gentlemen, I hope this can be of any help.

//juambo

PD English is not my mother language so Grammar Police comments are welcomed.