These are the chucks I use. I'm especially proud of them because I keep seeing stuff on metal chucks with chains and ball bearings and how they brake, and I can say I have the perfect chucks for me, they have a swivel base in them which has never broken on me. Neither on my fire chucks.

Here are the specs if your wondering:

14 inch length

hollow tube

anodized black aluminum (I used to work in an aluminum extrusion factory and found these guys lying in the scrap bin all anodized and heat treated and ready for me to cut and use.)

Small chain links - like dog leash size

the length of chain is just a little bit longer than the width of my hand.

and the weight is half a pound.

my chucks compared to the top of a computer case. I figured the top of a computer case is pretty universal so it will give you a good idea as to what I work with.

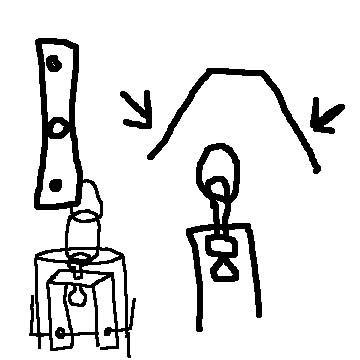

I tried to get a picture of how my swivel setup works. If this doesn't make sense the next one will.

top left is pretty much the pattern for a peice of sheet metal you cut and drill holes in. Granted I don't measure anything and wing it all, so I usually end up drilling the first hole and on of the side ones then bending it like in the picture on the top right and drilling the second side hole so it lines up.

I'm not sure how to explain how The swivel works, but check it. It will hopefully make sense.

In the end I have metal chucks that do have slight bumps on the side due to the bailing wire holding in the swivel joint in place, but you wrap some electrical tape around it and it works like a charm.

Just thought I would share this with you cause I see some metal chuck diy's but none of them have swivel joints and I personally need swivels on chain chucks. Cords no, but chains yes.

One more pic